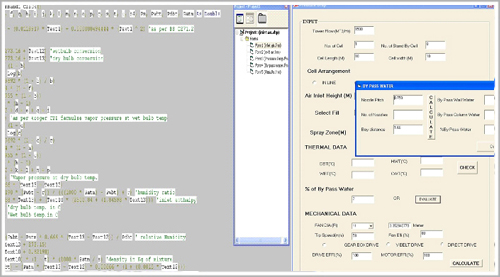

#Cooling tower designing software software

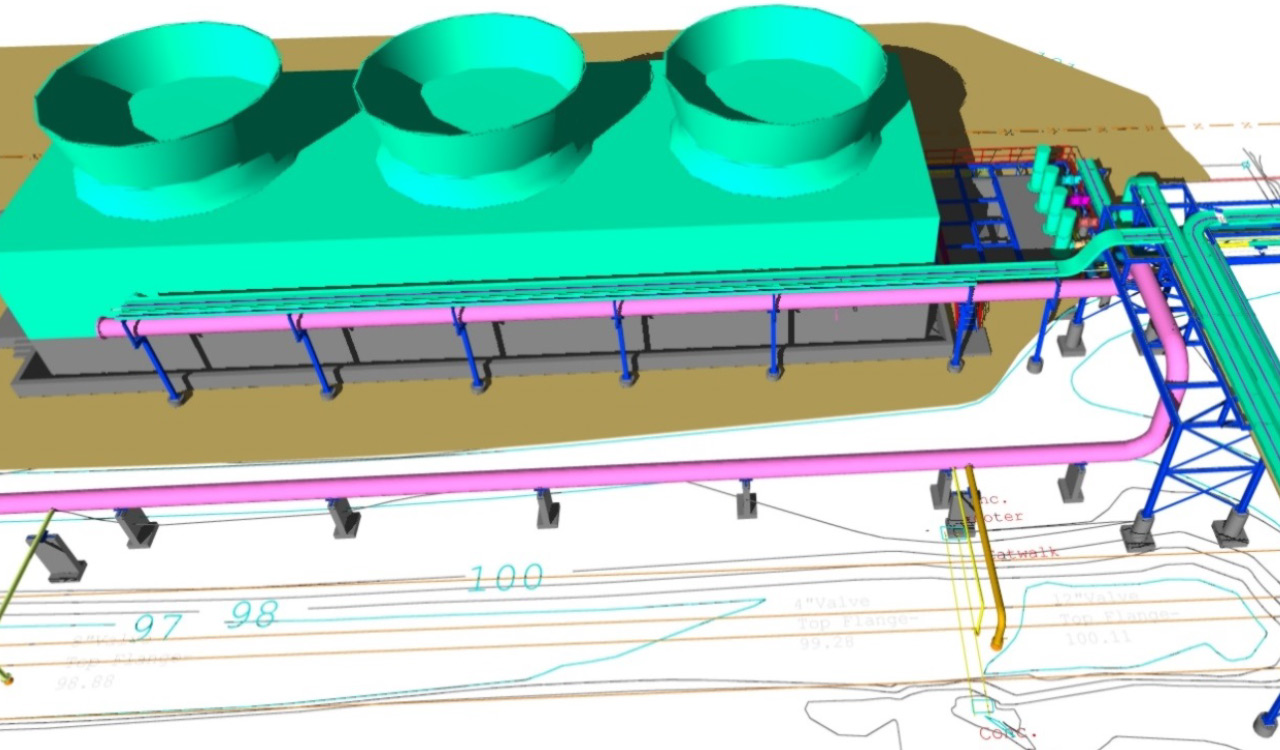

A calculation software can now fulfill this task based on real climatic data of any given location. Therefore, the comparison between different cooling technologies in terms of their sustainability is ever more important. The growing environmental awareness is pushing towards low impact solutions. Nowadays plant managers and engineers are more sensitive to resource optimization: a cooling system must combine performance with reduced operating costs. Often the choice of a cooling technology for industrial application or HVAC does not only depend on project performance requirements. We do not leave you alone in the selection: we study your plant and sector needs together with you. Technical Proposal Engineering and Project managementįirst goal: ask the right questions to the customer and involve him selecting the best cooler.Large-Scale Distribution and Supermarkets.MITA IoT Platform 4.0 for remote management of the cooler.MITA Systems Cooling Stations for tower water management.Reinforced Concrete Tanks for cooling tower water collection.Salinity Dosing and Control Stations for cooling tower water control.MITA Control System inverter for consumption optimization.Alchemist Subcooler to improve the efficiency in commercial and industrial refrigeration.MCE Industrial Condenser for gas condensing.MCC-T Modular Closed-Circuit Evaporative Cooling Tower for large systems with fluids to be kept unchanged.MCC Closed-Circuit Evaporative Cooling Tower with fluids to be kept unchanged.Economax Cooling Tower for Ice-Cream Parlous water saving for display cases, batch freezers and pasteurizers.MCT Open-Circuit Evaporative Cooling Tower with centrifugal fans also with electronic commutation.PU Industrial Cooling Tower field-erected.PMM Modular Cooling Tower for large industrial plants.PME-E Open-Circuit Evaporative Cooling Tower for medium to large systems.PMS Evaporative Open-Circuit Cooling Tower for small and medium plants.PAD-VR Adiabatic Condenser pad-vr adiabatic condenser.Adiabatic Dry Coolers and Adiabatic Condensers.

The result is a cooling tower that is low maintenance, economical and able to deliver a consistently high quality, problemfree performance. 'Cheap and cheerful' solutions such as fans with a V-belt drive, or painted panels, are avoided. This performance is achieved by a careful choice of materials - stainless steel combined with glass fibre reinforced polyester and plastics - the exceptionally sound design and the considerable experience of our engineers. We design and manufacture cooling towers that have a long life and require a minimum of maintenance. All structural design principles are analysed and tested in advance using dynamic calculations and computer studies.The expandable modular system has virtually no limitations in terms of shape and size.Due to their low profile, cross flow cooling towers present fewer aesthetic problems.The Polacel frost-proof polyester water pan can withstand sub-zero temperatures.

#Cooling tower designing software portable

The advanced design engineering has also resulted in a number of special structural advantages:

0 kommentar(er)

0 kommentar(er)